Whenever i want to work with my laptop i like to sit on Bean bang inside of chair just because comfortable sitting, But that is not allowing me to use Mouse, and unable to write due to uneven surface.

So i thougt that i will make a small foldable table on shopbot, which will gives me the all this comforts.

So i started finding the scrap material, and i get some plywood pieces from scrap yard.

According tm this plywood pieces i started the thinking of making the table.

Then i just make google search i got some ideas from those.

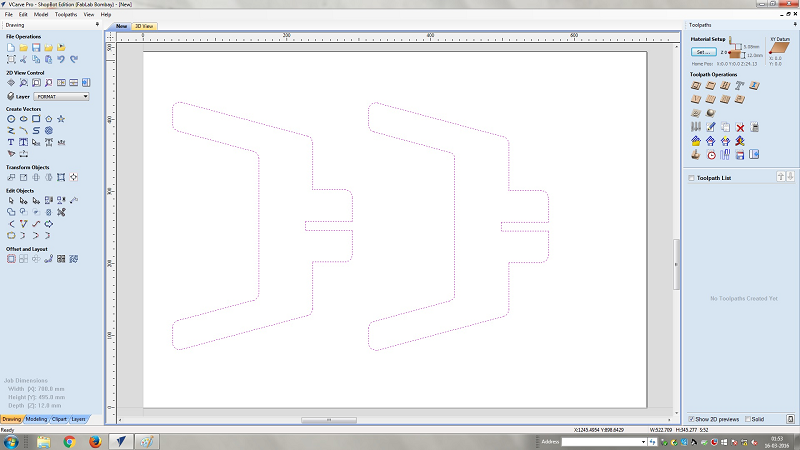

And I started making 2D drawing in solid works.

After lot of struggle and with help of my friend Yatin i done with my design.

Then i just Scale it done according Laser cutter 1:0.35 ratio and cut those parts on laser cutter and fix correctly, So my design is right.

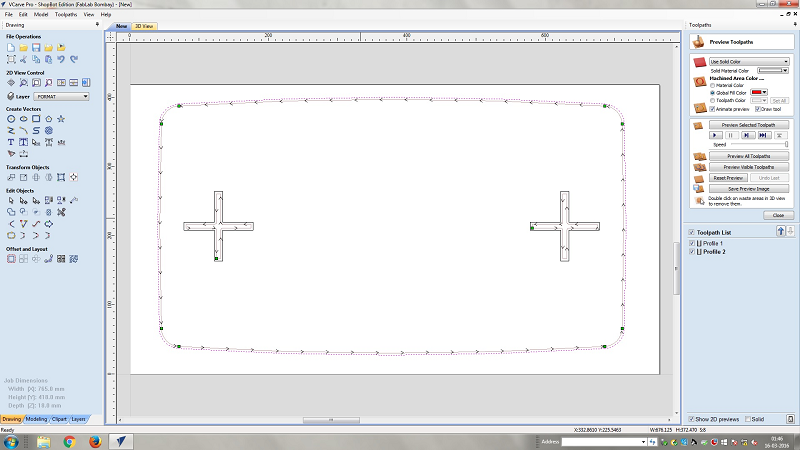

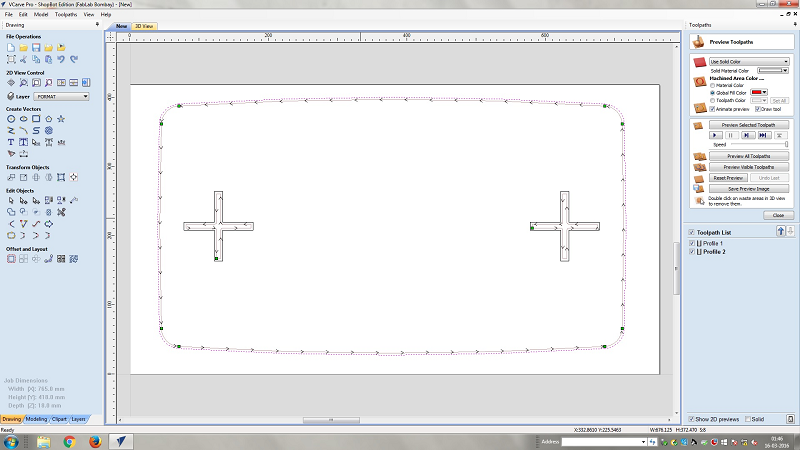

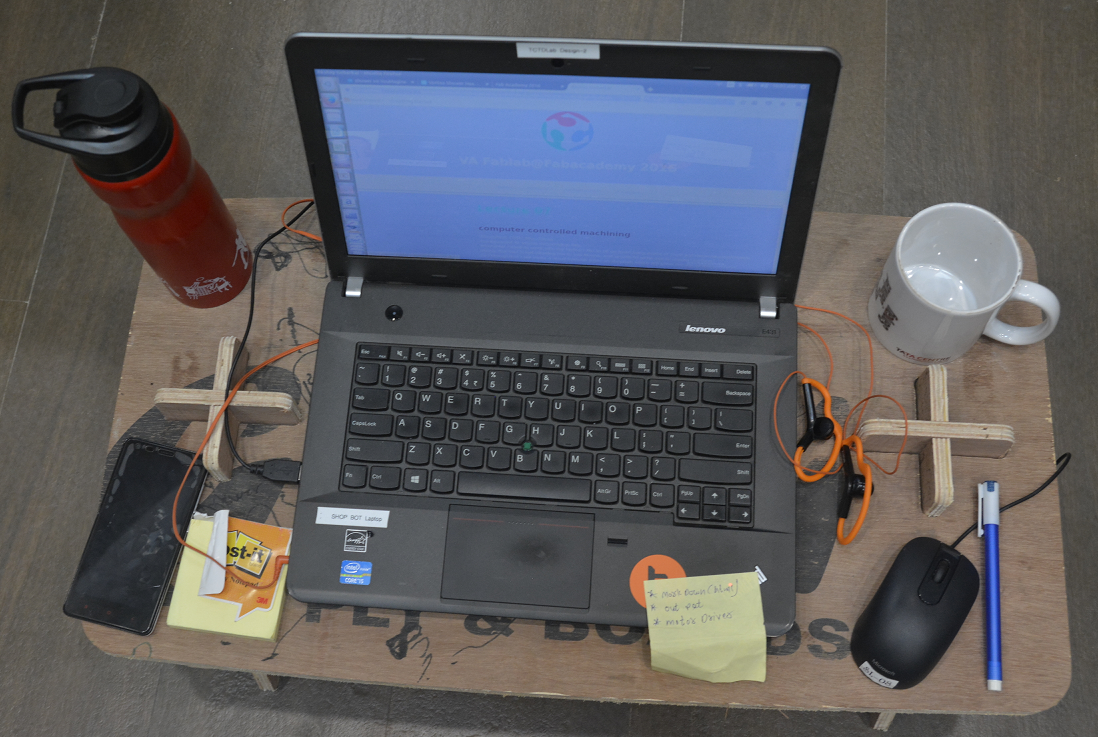

Then import my .dxf files into Vcarve pro(shopbot CAD&CAM software) For CAM(computer aided machine) and Selected the inner profile -> tool 57-900(6.25mm) end mill -> with 6 steps for 19mm trough -> feed rate 50 mm/sec -> plunge rate 25 mm/sec and calculated, Then i done same thing with outer cutting and saved both files into one file.

AS like upper file i saved all files into .sbp format

Then screwed Three plywood pieces separately using the makitha 18v drill machine.

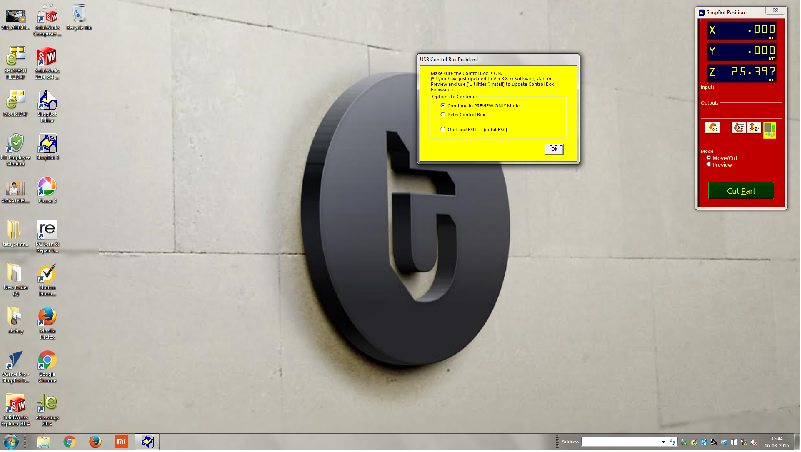

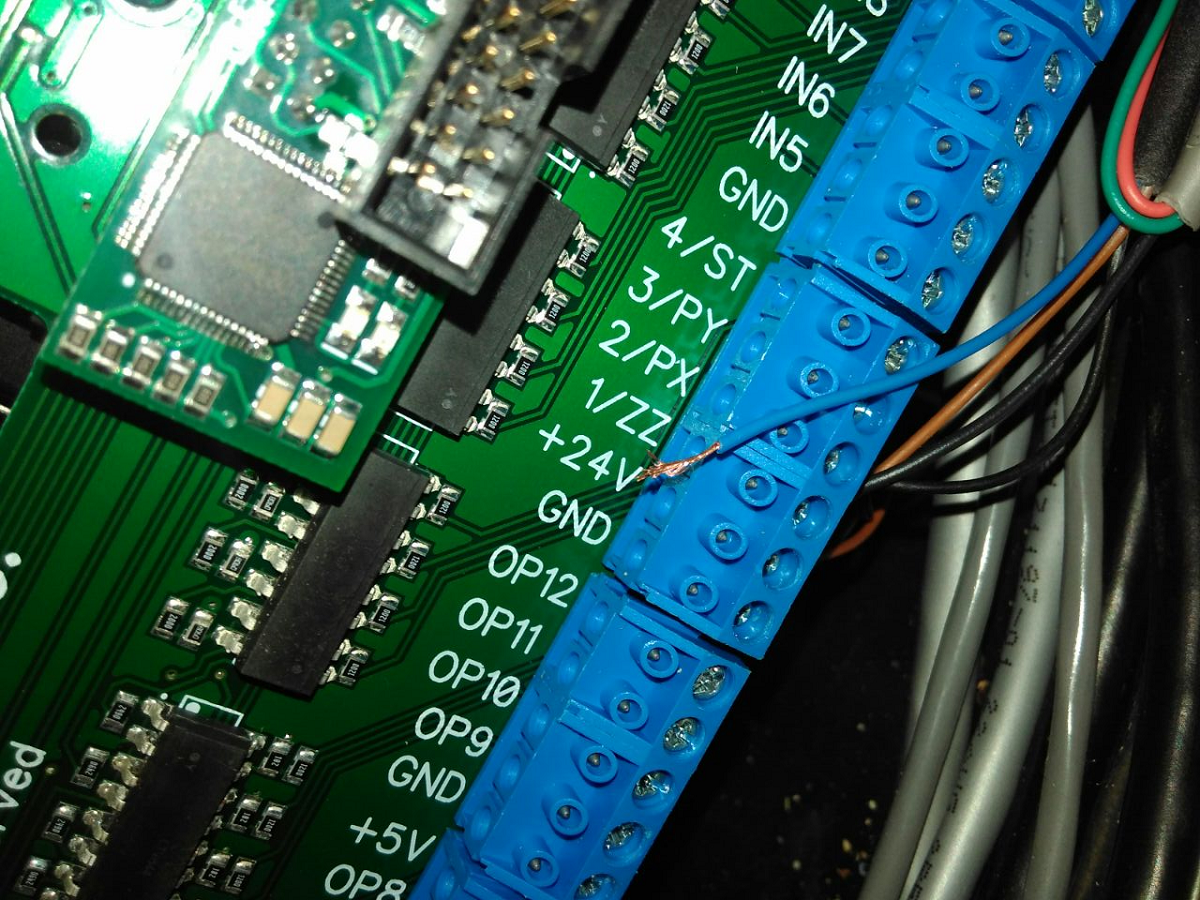

Then i went to shopbot machine start -> reset -> then started the shopbot3(machine software), but its showing me Previem mode only, so i checked all connectors and pix it correct port(If port will change then we need to make change into shopbot3 software also) and Restarted the PC.

After restarting the PC i made same thing but now its showing me the Utilities issue(Download firmware).

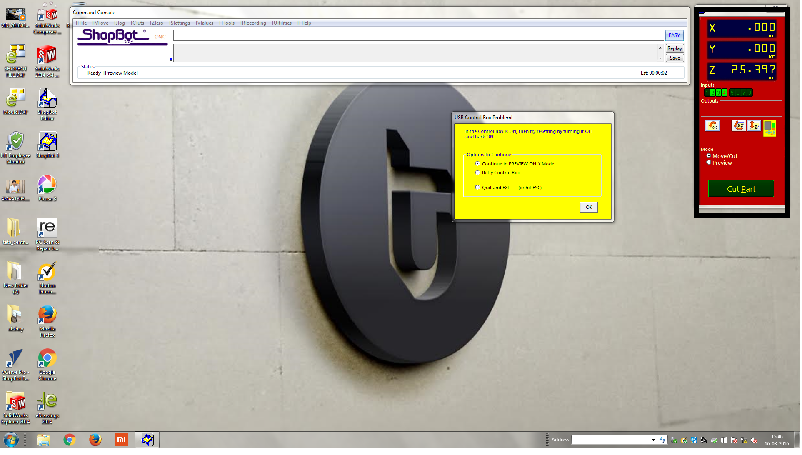

So i shifted to preview mode went to Utilities -> Firmware and followed the instructions which is there and Downloaded the firmware.

Now the machine is started done the reset and started the software now its working and showing me Move/cut mode, I ckick on "K" now showing me the key(X,Y,Z).

And moved the X,Y direction and set X,Y home postion,Then closed the keypad window.

I touch the aluminium plate to tool, so in Input numbers 1 is blinked then cliked on Z Zero, now tool is coming down and it touch the plate another time it went to up and comes down touched the plate and went to 25.397mm(1 inch) height and stoppes.

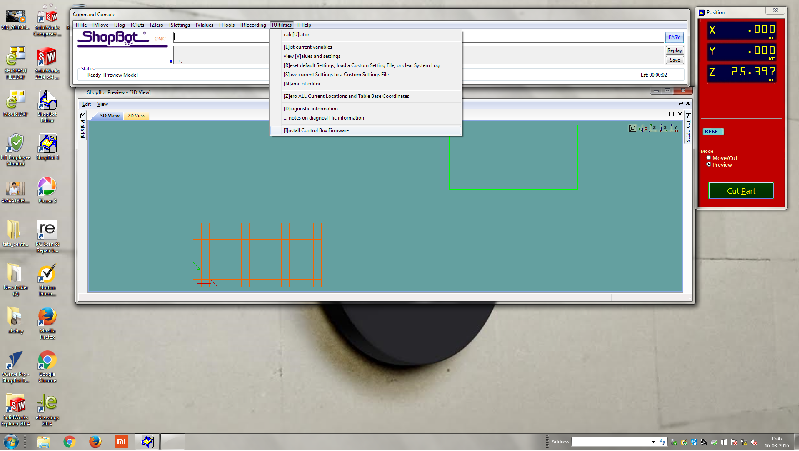

So now every thing is ready Ckicked on Cut part instide the .sbp file another window is started so i just want to check whether it is going properly or not, so i selected the 3D preview -> then start and now it doing air cut and its completed.

So every thing is ready and started the dust collecter and where's the "safety headphones and safety goggles" and went to "Start" command and started the spindel also it going.

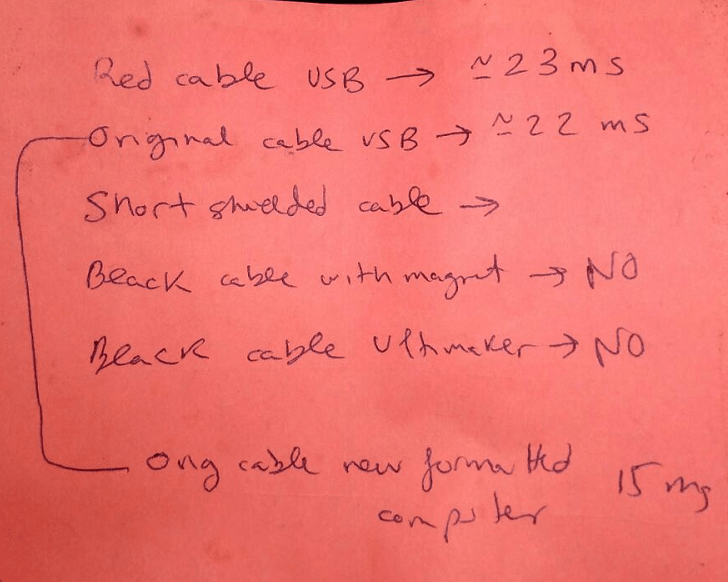

But while cutting inner path 5th or 6th step "X-130.682,Y-247.574" its just stopped there nothing is happening.

I tried several times but machine was not able to go behind the "X-130.682,Y-247.574" this postion.

But while doing this i got some errors 66,86,74 and 75 whenever iam getting this i just disconnected it and start it.

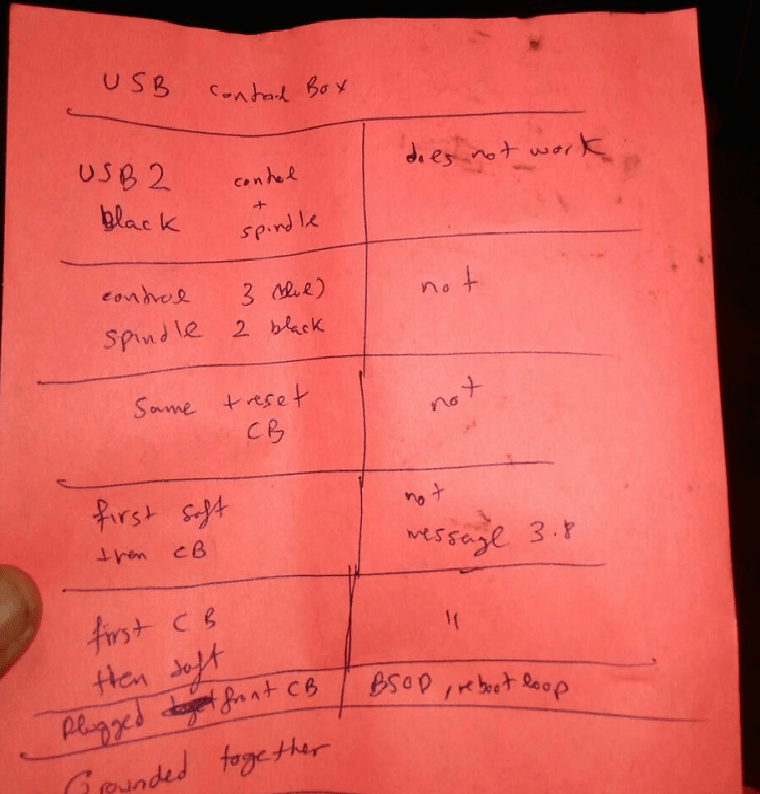

Me and support.shopbot people (Frank smith and Thomas Hartnett) talks on hangouts for hours and hours for more than a one week we tried every possible thing which we can do, But the result is same nothing is happening.

Then everything is possible for my Fab guru.

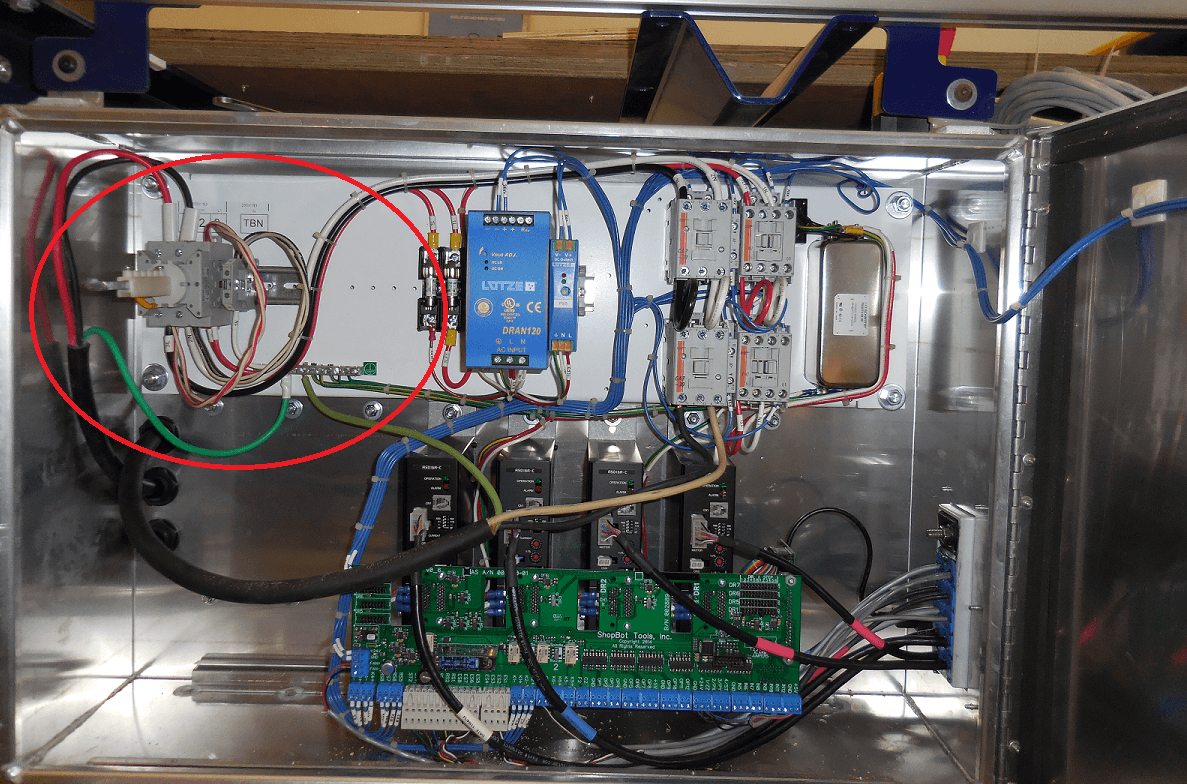

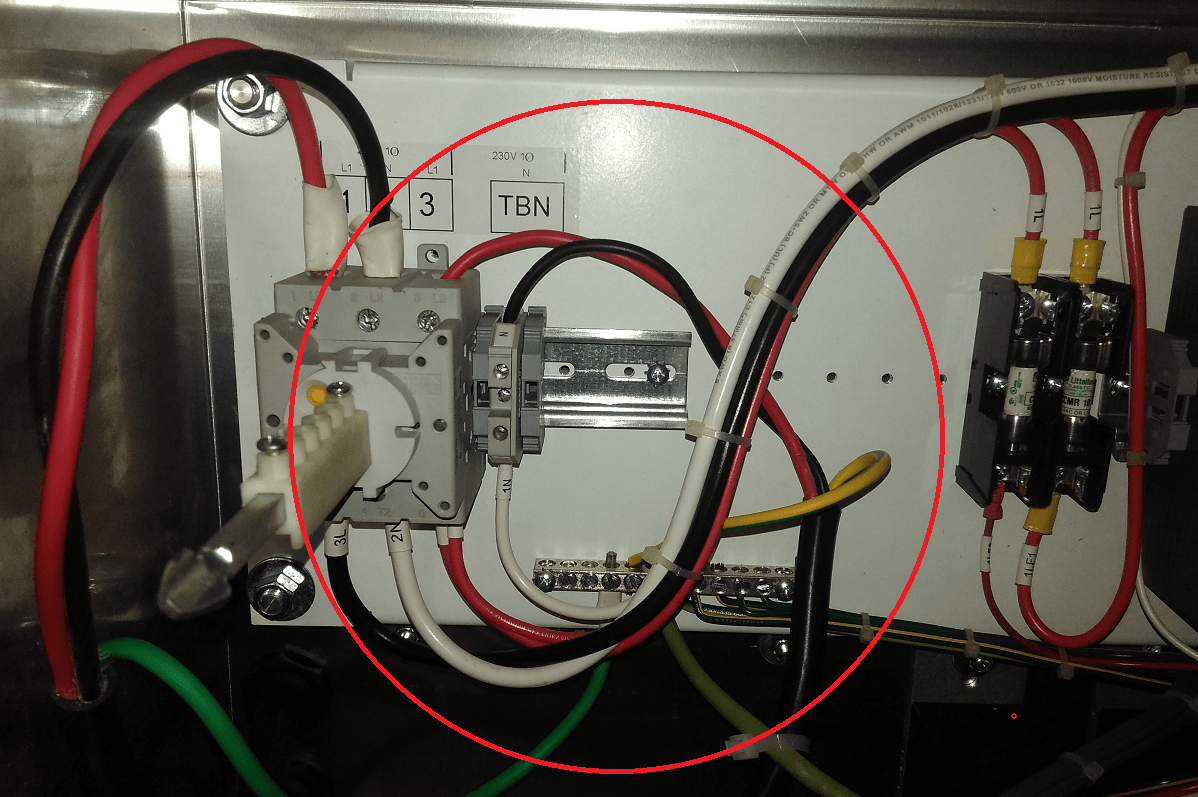

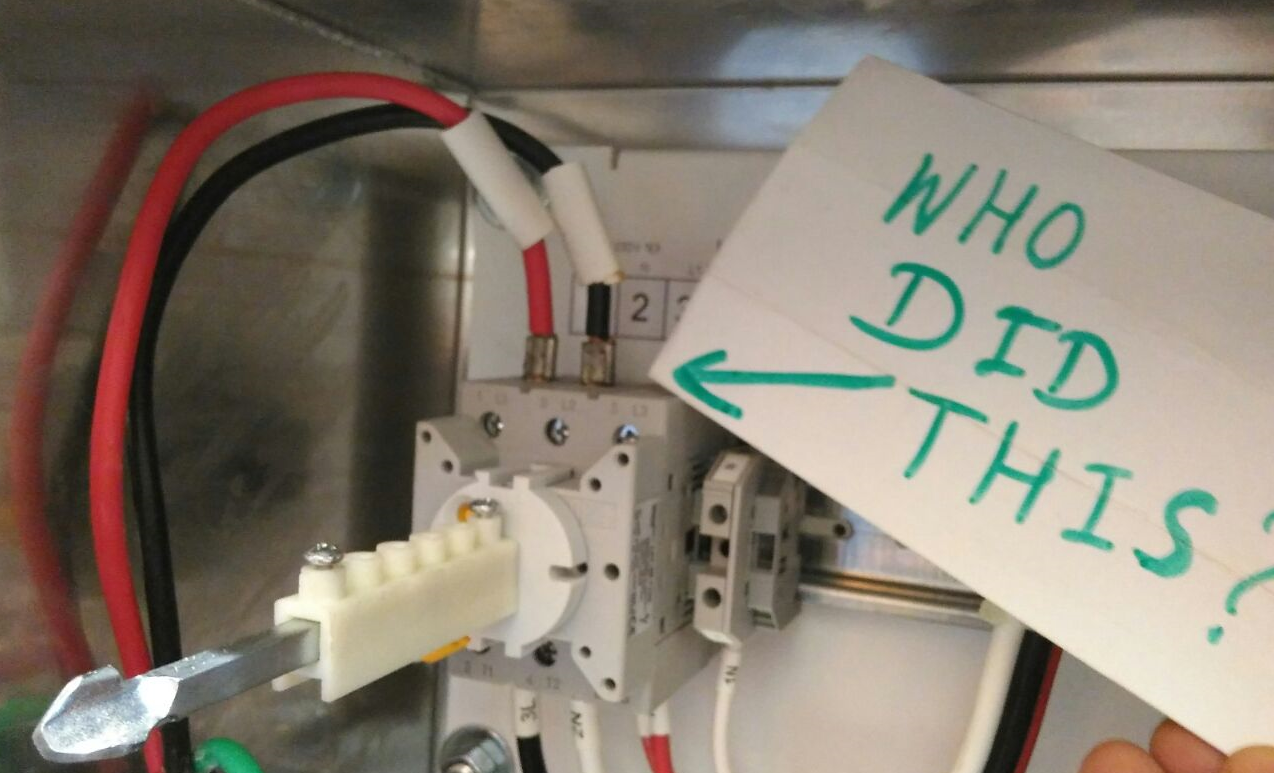

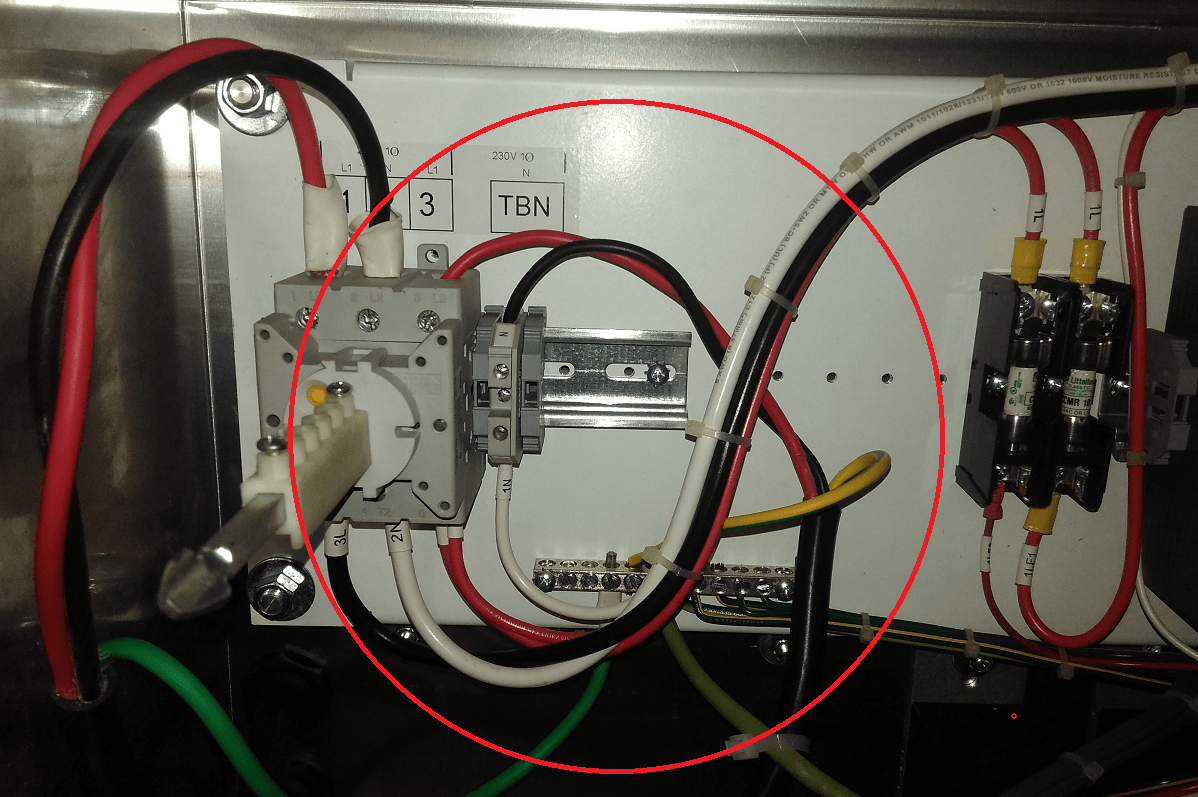

Now what we found the issue in shopbot control box, The connection for control box and spindel is same and just used the jumper wires for it.

Then we talks with Thomas from support.shopbot and separated the connections and fix it.

Now yes its working properly and i completed my assignment all process as i menstion so i just need to go for it

So set the three times X,Y zero(home postion) And Z Zero also and its done.

Removed all plywood pieces and done littelbit sanding on it.

Now i can sit on bin bang and work for fab academy

While using shopbot you must have to WEAR "Safety Headphones and Safety Goggles".

And also we have yellow line border to the shopbot and i never permit any one crosing that line.